Quality Control

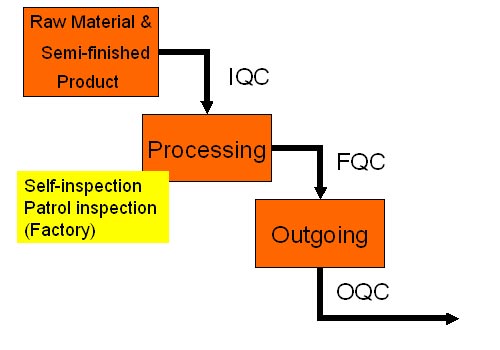

Salecom has a comprehensive quality control system, including a complete quality assurance department structure, well-equipped and precise testing facilities, and various quality system certifications as well as product safety certifications.